Most people use the term “foam rubber” and “sponge rubber” interchangeably, but the truth is they are different things. But if you work in the plastic or rubber industry you know there is some disparity between the two materials. While both foam and sponge are soft and squashy the two substances are quite different which exist in their ingredients as well as their molecular structure. This makes them have a different application both for industrial and home purposes. Therefore, choosing the right material is imperative because each substance works better in specific applications. For example, silicon foam is resistant to high temperatures that make them popular mass transit industry. Additionally, choosing the right rubber material is important because you need products that meet set requirements for flame, smoke, and toxicity. So the question is what is the difference between these two substances? This article has gathered some of the major differences between them in terms of how they are made, raw material, and their chemical properties.

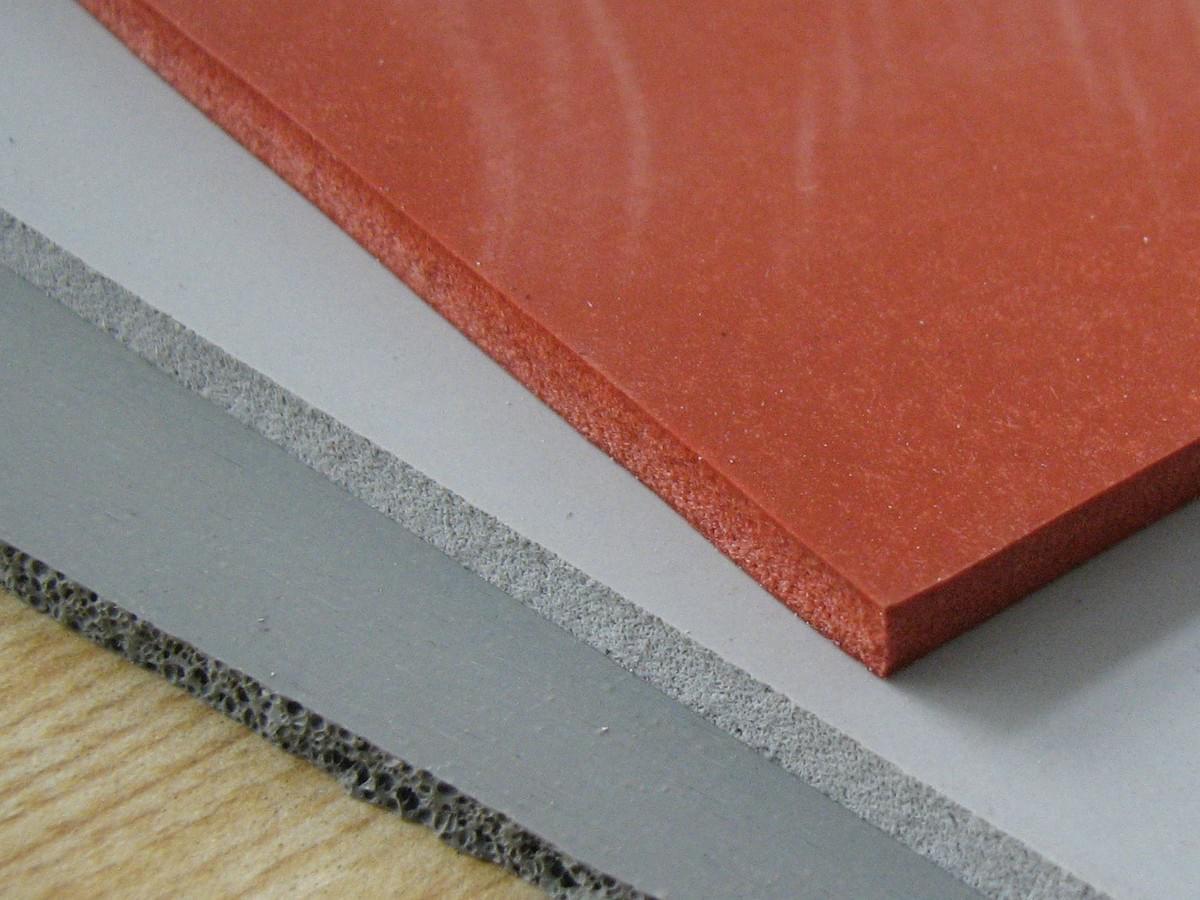

Looking at how they are made foam rubber is typically made through a blowing agent. The blowing agent helps in forming gas bubbles in a plastic mixture which is generally a mixture of water, polyols, polyisocyanates, and additives such as colorants, flame retardants, and fillers. The foaming process is either a continuous process to make laminate or a batch process to make a variety of foam rubber shapes by cutting or molding. Sponge rubber may appear similar to foam rubber, but they are not the same thing. There are two main types of sponge rubber namely open cell and closed cell sponge rubber. The open cell sponge rubber has open, interconnected pockets that allow passage of water, air, and other chemicals when the open cell sponge rubber is uncompressed. However, a closed-cell sponge rubber has balloons like pockets or cells that hold nitrogen gas which prevents the passage of air, water, or other chemicals at low pressures. Open-cell sponge rubber is made by heating mixed ingredients in a mold where sodium bicarbonate is added. Adding sodium bicarbonate in the mold makes the unsecured sponge rise like a cake making tiny interconnected cells. In the case of closed sponge rubber chemical powder that decomposes under heat is added which induces the release of nitrogen giving the closed sponge rubber its firm compression.

The other disparity exists in their uses. Foam rubber especially polyurethane foams is used to control vibrations and for shock absorption, especially in the automobile industry. With Polyurethane foams the high the density the more energy they absorb. These foams do not enlarge when compressed making them an ideal choice when one has no enough space. Polystyrene foam rubbers are rigid, tough, and lightweight, and they have high moisture resistance. They are good in applications that where weight is needed to a bare minimum while maintaining the stiffness of the material or products. Sponger rubbers on the other hand are made from a variety of materials such as silicon, neoprene, nitrile among other materials. Most applications of sponger rubbers are for shock absorption and are good at providing controlled compression and recovery on gaskets. Open-cell sponges are used in prosthetics, electrocardiogram pads, clinical sponges among other areas. The closed sponge is used in vibration dampening, soundproofing, and thermal insulation among other things. Those are some of the major differences between foam and sponge rubber. Visit this website for more Custom Molded Products.